Multi-disciplinary Plant Engineering & Documentation Services

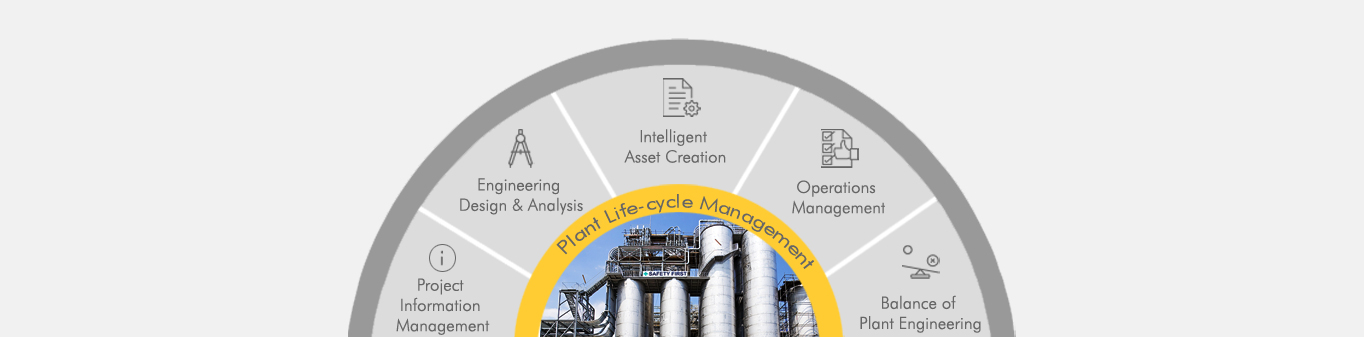

Neilsoft provides multi-disciplined plant engineering services including Pre-bid engineering, Extended Basic Engineering Support, Plant Digitization, Detailed Engineering and Design, and Plant Documentation services for (plant) operations and control.

Today, plant owners, operators and other stakeholders face global competition, low cost pressures, tighter construction norms and reduced time-to-market requirements. Moreover, the dramatic shifts in contracts(LSTK) and technology-driven design, procurement, and construction of projects to improve overall efficiency and reduce a cost(s) is a focus of every organization.

Intelligence, integration and modularity are the major future (plant) trends for cost reduction and faster plant engineering. Neilsoft with its multi-disciplinary (Process, Piping, Mechanical, Civil Structural and Electrical & Instrumentation) capabilities and BIM-enabled processes provide efficient plant design & equipment engineering services to owner-operator, EPCs, EPCM, OEMs and technology providers. We help companies to realize their core strategic expectations from the plant project, improve their competitiveness, minimize project risks, and help optimize project completion times, hence reducing the overall project cost.

Whether you are expanding, upgrading, revamping/scaling-up existing plants, or establishing new plants, you can rely on Neilsoft’s cost-effective plant design services & solutions to help you achieve your business objectives.

We combine engineering and project management expertise & resources with strong domain experience to create value for our customers. Our team is equipped with a good understanding of various code's & standards, software platforms, and technologies to support clients in delivering projects across different locations in India, Middle East, Asia Pacific, USA, and Europe. We specialize in setting-up dedicated teams to support our customers continuously for their multi-project and multi-geography requirements.

Industries served include chemicals, specialty chemicals, oil and gas, power generation, mining and minerals, food & beverages, pharmaceuticals, etc.

Focusing on Efficiency improvement areas for creating Business Value

Efficient Project Information Management

- Cost Estimation

- Tender/Proposal Engineering

- Pre/Post Bid Support

- Preliminary PFD/P&ID

- Preliminary Bill of Material for the plant areas

Basic Engineering Design Support & Analysis

- Sizing/Optimization of Pump/Pipe/Utilities

- Mechanical Static Strength Calculations & Equipment Sizing

- Highly Optimized Skid Design

- Pipe Flexibility Analysis

- Civil & Structural Design Optimisation

- Electrical Equipment Sizing/Optimization using ETAP

- Industrial Automation - End of Line Automation

Creating and Managing Intelligent Asset(s) by Digitization

- Legacy Conversion - P&IDs/SLD in intelligent format

- Conversion from Laser Scan to 3D Model

- BIM in Plants for Standardization

- Creation of Catalogs – Material/Vendor-specific (as per organization standards)

- As-built Engineering (after construction or operating plant)

Balance of Plant (BOP) Engineering

- Tank Farms

- Piperack

- Utilities (Water/Air/Steam/Fuel, etc.)

- WTP/ETP/STP – Package Engineering

- Switchyard & Substation design

- Industrial Instrumentation/Control & Automation

- HVAC & Firefighting Package Engineering

- Material Handling Work Package

- Industrial Architecture for Non-Plant & Plant buildings

Engineering Documentation for Efficient Operations Management

- Asset Management with Intelligent tagging system

- Structured Engineering Documentation & Reports for Plant Operations & Maintenance

- Planning, Controlling, Scheduling, Monitoring and generating reports – for Plant Inventory

Follow us on Facebook

Follow us on Facebook Follow us on Twitter

Follow us on Twitter Watch us on YouTube

Watch us on YouTube Join us on Linkedin

Join us on Linkedin Follow us on Pinterest

Follow us on Pinterest